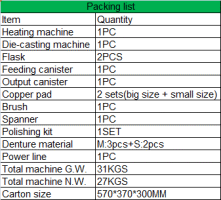

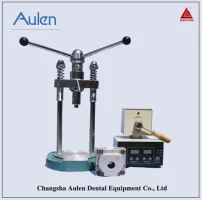

High quality dental machine/ injection system/manual machine for dental lab use

Operating Instructions:

A.Fixed the die casting machine on the working platform, the height should be convenient for operation and melting materials.

B, Using Plastic injection moulding machine before, please check if the nut of die-casting machine is tightened. Please connect the power first and check each parts correct and safe conditions when you operation.

C, Wiping isolating oil on the inner side of the feeding canister evenly, then insert the canister into the electrical furnace, press panel power switch, connect the electrical power on the machine to warm up and static display of heating temperature, heating time of the factory settings.

D, Until warm-up time about 25 minutes, the temperature reached the required value.

E, Adjust the heating temperature, heating time (factory setting is 287°C , 14 min) ,you can through the top of each (+,-) buttons on the panel to adjust the heating temperature & heating time before press the start button.

Note: The heating temperature, heating time can be adjusted according to the requirements of material, most of the material does not need to be adjusted. Each time heating temperature, heating time back to the factory values.

F, After the temperature stabilized, put the metal pad, aluminum pipe fitting materials into the feeding canister.

Note: The inner of feeding canister, metal pad, aluminum tube need to wipe isolating oil evenly, first into the aluminum tube, and then into the metal pad (curling outwards).

G, Press the start button to heat the material, when the above button show green light, the heating time will flickering and the number will fall evenly, when the heating time finished, the alarm will ring, take the feeding canister out quickly, and let the feeding canister correctly and stably to put on the flask for casting, the pressure need to maintaining 1 to 2 minutes when the material put into the flask.

H, When the work is finished, please turn off the power switch and unplug the power cord.

Note:

A, After casting the materials, the remaining waste into the feeding canister, it can be put back into the output canister and using the die casting machine pull out.

B, When using the flask, please wipe release agent or lipids before filled plaster in the flask.

C, When take out the plaster, it should be put flask four sides stably and can not let one side higher to take out the plaster.